Product Information

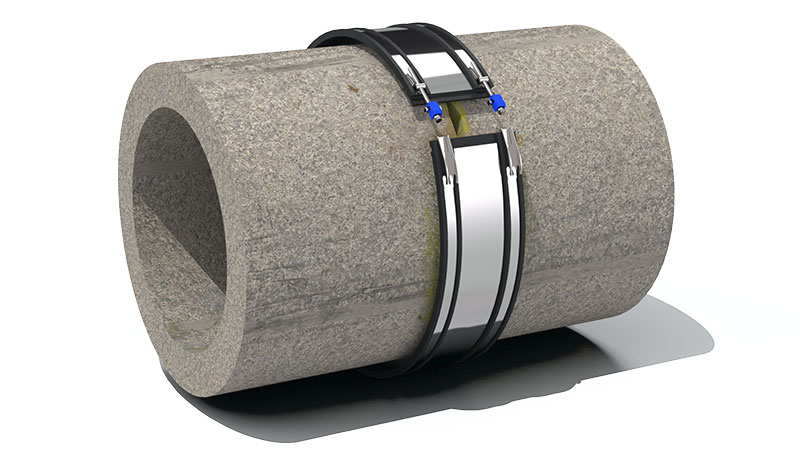

The WRC/MAGWRC couplings are designed for the repair of damaged pipes. To install the split repair couplings, it is not necessary to remove a piece of pipe from the pipe, which considerably reduces the time and material required during repairs.

The Fernco WRC/MAGWRC couplings are characterized by several special features. They can be easily and quickly assembled without losing their sealing performance and reliability against the conventional design. The WRC/MAGWRC couplings are available in any size from 300 mm to 2100 mm.

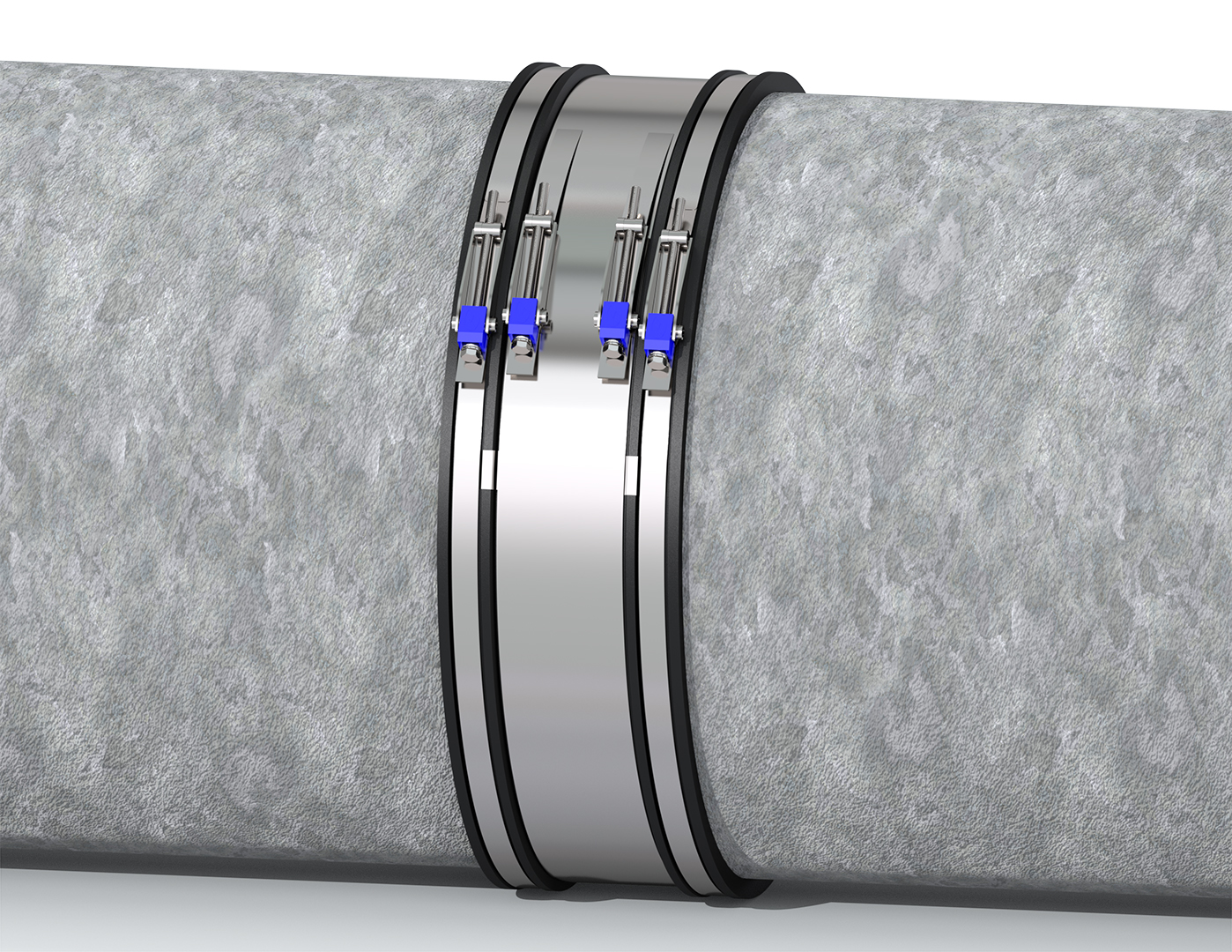

The difference between the WRC and the MAGWRC coupling is the width of the EPDM seal. The extra-wide version of the MAGWRC repair collar (370 mm) is excellent for repairing larger cracks or damage, as it provides a wide area to seal the damaged area. The WRC coupling is 190 mm wide and suitable for narrow cracks and small damages.

The split pipe repair couplings are calculated according to your specifications and produced individually. Up to 620 mm the sizes are available analogous to the standard couplings type 2B (see SC 310, SC 320 etc.). From 620 mm upwards, the WRC is manufactured with the massive LC clamping system in mm increments (621, 622, 623, …). In principle, however:

Size of the coupling = OD pipe ± 10 mm

The clamping range of each WRC/MAGWRC coupling is 20 mm! The designation WRC 6xx merely indicates the price category and states that WRC coupling in the range of 586 to 685 mm have the same price. It does not mean that the clamping range is from 586 to 685 mm. When ordering, please specify the exact outer diameter of the damaged pipe, measured at the point of damage!

Except for the EPDM rubber sleeve all Wraparound Couplings confirm DIN EN 294-4.

The wraparound coupling are quick and easy to install as it is not necessary to remove a piece of pipe from the line:

Wrap the rubber coupling around the pipe where the repair is needed

Apply adhesive to the end of the profile and press down for a few seconds

Apply a few drops of adhesive to the metal bridge and press it onto the joint

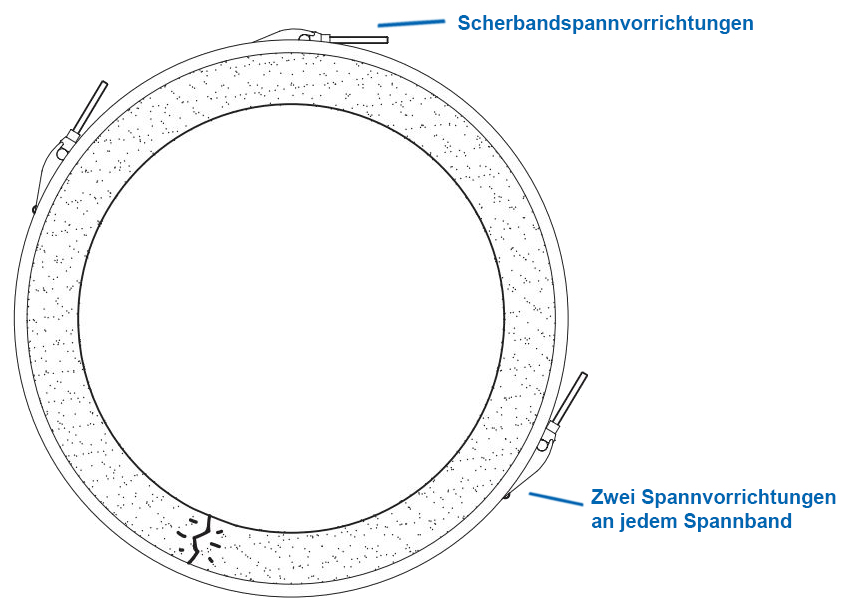

Add shear band and tensioning straps around the coupling and tighten them equally